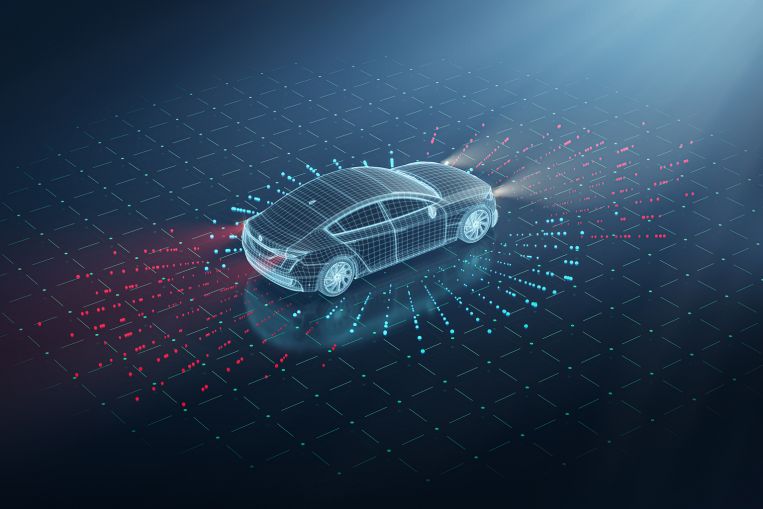

One thing the pandemic has taught us is to expect the unexpected. In March last year, as the scale of the looming Covid-19 crisis became clear and economic activity the world over ground to a halt, few would have predicted the nascent market for electric vehicles (EVs) would move into the fast lane.

Yet, that’s exactly what happened. According to the International Energy Agency (IEA), global EV sales surged some 40 per cent in 2020 from the 2.1 million electric cars sold in 2019.

Indeed, EV sales continued to climb despite the dislocations of the global pandemic and a broader 15 per cent year-on-year fall in overall auto sales through that same time period.

But before we bid a fond farewell to the internal combustion engine (ICE), consider the following. Even with this latest increase in sales, the overall EV market share remains low at just over 4 per cent. By 2030, according to the IEA, that figure will have barely shifted: EV stock across all modes would still only account for just 7 per cent of the road vehicle fleet.

BNY Mellon Investment Management believes this recent narrative on EV highlights both the promise and potential pitfalls of the transition to new forms of mobility.

On the positive side of the ledger, a continued reduction in EV battery costs offers the prospect of lower pricing and increased sales. Likewise, sustained policy from governments to improve air quality, reduce greenhouse gas emissions, improve energy security and develop new economic opportunities should also help drive wider adoption.

Over the long term, this means that the roads of the future could be quieter, cleaner and less environmentally damaging as EVs take the place of fossil fuel-reliant ICEs.

Yet, as ever, there are challenges. For starters, consider the question of resources and copper in particular.

Electric vehicles rely on a far greater intensity of the metal than their ICE brethren – largely in the motor coil that drives the engine. For an average gasoline-powered car, for instance, about 20kg of copper, used mainly in the wiring, will suffice. For a hybrid, that figure comes to 40kg.

Yet, for a fully electric car, the copper requirement is double at 80kg.1 Size also matters – the bigger the vehicle, the larger the copper intensity. A fully electric bus, for example, will use between 11 and 16 times more copper than its ICE equivalent – depending on the size of the bus and its battery.2

No surprise, then, that copper pricing soared 60 per cent over the past 12 months to trade above US$10,000 (S$13,540, approximately) a tonne earlier in the year for the first time in a decade.3

Batteries, too, are resource-intensive, with demand for lithium and cobalt – crucial components of today’s lithium ion battery technology – forecast to increase 18 and 37 times respectively by 2030 relative to consumption in 2015.4

Then, there’s the question of infrastructure. As with filling stations for conventional petrol and diesel-fuelled cars, charging infrastructure is a crucial component of the EV market.

While BNY Mellon Investment Management’s research says global public charging infrastructure has grown at an average of over 60 per cent annually from 2013 to 2018, reaching some 600,000 charge points, it believes multi-billion dollar investments in localised charging stations and local electricity distribution networks will still be needed to meet charging demand as EVs gain scale.

Winners and losers

So where are the winners and losers in this scenario of a transition to a cleaner, greener world of mobility?

One obvious place to start when considering the winners is to consider the resourcing question, says BNY Mellon Investment Management. Here, the team notes that over time, the world’s producers of copper, cobalt, rare earth elements, graphite, nickel, aluminium and lithium will likely benefit from increased demand.

Battery providers and electronics firms also stand to gain as these companies may benefit from the increase in the number of EVs being manufactured, and therefore higher demand for the technology powering them.

In contrast, the traditional auto parts industry may lose out in the longer term as pure EV penetration increases. Largely, this is a function of the increased simplicity of EVs versus ICE cars. With no need for carburetors, fuel injectors, pistons, pumps, filters and all the associated paraphernalia of petrol combustion, there is hence less need for the companies producing such paraphernalia.

However, BNY Mellon Investment Management still believes there are near-term opportunities for the traditional autos suppliers to benefit from higher content in plug-in hybrid electric vehicle models that overcome the so-called range anxiety – driver concerns about the limit of miles driven per battery charge – associated with full EVs.

Geographic concentration

From a global investment perspective, BNY Mellon Investment Management’s research team notes that the global automotive industry currently suffers from high geographical concentration, with the top five producers of autos (China, the United States, Japan, Germany and India) accounting for over 60 per cent of global auto production.

BNY Mellon Investment Management believes countries with large production shares combined with large surpluses will likely face the most macroeconomic risk if they are unable to maintain the same market share in EVs as they have enjoyed in the age of the internal combustion engine.

However, the team points out it is also important to consider that many original equipment manufacturers (OEMs) for the automotive industry are multinationals. This could mean that the fate of any given automotive manufacturing country may ultimately be intertwined with that of others, spreading risk and opportunity more widely across geographies.

Commenting on the likely impact of the rise of the electric vehicle market on investors, BNY Mellon Investment Management head of global rates and macro research, Mr Gareth Colesmith, says: “The impact of EV proliferation will be widespread, at both a corporate and a country level. That means investors will need to take these factors into account when analysing their portfolios.

“Pace of adoption is a key variable that could determine how great an impact the shift to EVs has on various areas of the market, as ultimately a speedy transition would make it more difficult for corporates, the energy sector and countries to adjust. Investors can better gauge the potential impact on their investment portfolios by examining how the rising demand for electric vehicles may affect investments in the automobile sector, the energy sector and country exposures.”

Footnotes:

¹ Mining.com: ‘EV sector will need 250% more copper by 2030 just for charging stations’, Aug 12, 2019.

² Ibid.

³ Financial Times: ‘Copper hits 10-year high above $10,000 a tonne’, April 29, 2021

⁴ Applied Energy: ‘The EV revolution: The road ahead for critical raw materials demand’, Dec 15, 2020.

Important Information:

Not for further distribution. This is a financial promotion and is not investment advice. Any views and opinions are those of the investment manager, unless otherwise noted. The value of investment can fall. Investors may not get back the amount invested. BNY Mellon is the corporate brand of The Bank of New York Mellon Corporation and its subsidiaries. In Singapore, this document is issued by BNY Mellon Investment Management Singapore Pte. Limited, Co. Reg. 201230427E. Regulated by the Monetary Authority of Singapore (MAS). This advertisement has not been reviewed by the Monetary Authority of Singapore.

MC849-09-24-2021 (6M)